Motion Control – Four Axes Positioning Stages

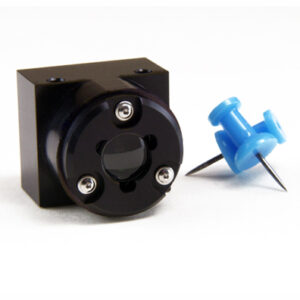

Van Nuys, CA – Motion Control – OES (Optimal Engineering Systems, Inc.) has added to their extensive line of purpose-built stages. The new XYZR Series of Four-axes Stages are the integration of a: 15 mm, 30 mm, 50 mm, 75 mm, or 100 mm linear stages (in any combination) for the X, Y, and Z axes, and a 60 mm or 100 mm diameter rotary stage capable of 360 degrees of continuous rotation. These stages are the ideal choices for: Laser scanning, drilling, and machining, reverse engineering, inspection, assembly, measurements, tracking, and positioning.

This series of four axes motion control stages feature four motor options. The -01 option is Stepper Motor driven, the -02 option is Three Phase-Servo Motor driven with a Quadrature Optical Encoder, the -03 is DC Servo Motor Driven with a Quadrature Optical Encoder, and the -04 option is Stepper Motor Driven with Quadrature Optical Encoders for position verification.

Each axis of these black anodized aluminum alloy stages features high precision crossed roller bearings. The 15 mm, 30 mm, 50 mm, 75 mm linear axes feature high precision 1 mm per turn lead screws and the 100 mm linear travel stage has a 4 mm per turn lead screw. Typical repeatability and positional accuracy of a stepper motor driven stage is 10 microns. For higher resolutions and greater travel speeds select one of the closed loop servo motor options.

The rotary axis is equipped with a HOME switch to signal the motion controller the ZERO position. Each rotary axis has a pattern of precision mounting holes for mounting tooling and the 100 mm diameter stage has a thru hole. The linear axes are equipped with limit switches to signal the motion controller that end of travel is reached.

Each of these stages can be ordered with a fully plug-and-play compatible multi-axis motion controller for any motor combination from OES.

About OES – Optimal Engineering Systems, Inc. (OES) is a manufacturer of motion control products including: Stepper motor controllers and drivers, solenoid electronics, and positioning stages and slides. Applications include: Animation, automated assembly systems, automation, CNC machines, flight simulation, inspection systems, linear and rotary stages, machine tools, medical devices, motion control camera boom systems, optical comparators, CMMs, pan-tilt gimbals, PCB assembly & inspection, pick-and-place, positioning stages, robotics, scanners, security cameras, telescope drive mechanisms, time-lapse photography and winders.

Some of the industries OES serves are: Aerospace, Astronomy, Chemical, Communications, Educational Institutes, University, Colleges, Government Agencies, National Labs, Manufacturing, Medical, Metrology, Military, Motion Control, Museum, News Agencies, Semiconductor and Test Equipment. Optimal Engineering Systems, Inc’s. competitive advantage is its state-of-the-art in-house manufacturing facility in North America enabling OES to supply clients with custom designed orders or high volume just-in-time deliveries globally.

For additional information, contact sales team at: OES, 6901 Woodley Ave.; Van Nuys, CA 91406; Telephone: 888-777-1826 or +1 818-222-9200, FAX +1 818-436-0446 or E-Mail: sales@oesincorp.com or visit the website at http://www.oesincorp.com

See this and other Motion Control Components from OES (Optimal Engineering Systems, Inc.) featured on:

OES is now on YouTube …..https://www.youtube.com/watch?v=wdUzIagcMYc

http://MotionControl-XYZ-Theta.com

http://LinearMotionBlogger.com

http://MotionControlBlogger.com

http://MotionControlBuyersGuide.com

http://Catalogs-MotionControl.com

April 6th, 2023

April 6th, 2023  Editor

Editor

Posted in

Posted in