Motion Control – New Harmonic Drive HPF Series: High-Performance Hollow Shaft Gear Unit

February 23rd, 2026

February 23rd, 2026  Editor

Editor Motion Control Stage- Compact, Open Aperture Voice Coil Stages Features 1 Micron and 30 Micron Positioning Resolutions!

February 16th, 2026

February 16th, 2026  Editor

Editor Motion Control Stage- Hollow Core Voice Coil Stage

Van Nuys, CA – Motion Control Stage- The compact open aperture HCDS-051-032-013-01-B1-30 and the HCDS-051-032-013-01-B1-01 Voice Coil Stages from Moticont have a foot print of just 2.000 in. (50.8 mm) wide by 5.000 in (127.0 mm) long and feature positioning resolutions of 30 microns and just 1 micron respectively. These precision stages allow the user to select the level of precision needed for an application.

Motion Control – USDA Certified Stand-Off Bearing Flange Blocks with Si3N4 Silicon Nitride Hybrid Bearings, Set New Standard for Performance and Hygienics!

February 9th, 2026

February 9th, 2026  Editor

Editor Motion Control – USDA Certified Stand-Off Bearing Flange Blocks

E. Longmeadow, MA – Motion Control – FDA/USDA Certified, two, three and four post, Stand-Off Bearing Flange Blocks are setting a new standard for performance and Hygienics. These new Stand-off bearing flange blocks now available from LM76 reduce the surface area where mold and bacteria can thrive, even from the most through sanitizing operations.

Motion Control – Linear Focus Actuator from Equipment Solutions!

February 2nd, 2026

February 2nd, 2026  Editor

Editor Motion Control – Linear Focus Actuator

Forestville, CA – Motion Control – The LFA-1205 Linear Focus Actuator is a high performance compact positioning system. It was specifically developed for optical applications requiring both high precision and high-speed positioning over a short to medium stroke.

Motion Control Innovations – YouTube Channel features High Precision Stages from Optimal Engineering Systems!

January 26th, 2026

January 26th, 2026  Editor

Editor Motion Control Innovations – Visit the OES YouTube Channel!

Van Nuys, CA —– Motion Control Innovations -Videos Optimal Engineering Systems, Inc. (OES) has unveiled their new YouTube Channel https://www.youtube.com/@oesmotioncontrolvideos. Checkout their new video featuring the AK110-10-15 Alpha-Beta Dual axis Goniometer Stage.

Innovative Motion Control – Select from a Series of Low-Profile Push/Pull Type Solenoids to Meet the Specific Voltage, Duty Cycle, and Force Requirements of Your Application!

January 19th, 2026

January 19th, 2026  Editor

Editor Innovative Motion Control – Compact Push/Pull Solenoids

Innovative Motion Control – Van Nuys, CA –Magnetic Sensor Systems (MSS) has released 18 low-profile Push/Pull Clapper Solenoids with the ampere turns (windings) adjusted to meet the specific force and duty cycle requirements of an application. The S-66-100 Series of Low-Profile Clapper Push/Pull Type Solenoids from MSS are just 1.00 in. in diameter and 0.66 in. deep.

Motion Control – Electromate Introduces Advanced UAV and Drone Subsystems in Partnership with maxon

January 12th, 2026

January 12th, 2026  Editor

Editor Motion Control – UAV and Drone Subsystems!

Vaughan, Ontario, Canada — Motion Control – Electromate, a leading Canadian distributor of high-performance mechatronic solutions, is pleased to announce the availability of advanced UAV and drone subsystems through its partnership with maxon, a renowned Swiss manufacturer of precision drive systems.

Motion Control – Low Cost Linear Optical Encoder Module and Linear Scale Feature 1.25 Micron Resolution!

January 5th, 2026

January 5th, 2026  Editor

Editor Motion Control – Linear Optical Encoder Modules!

![]()

![]()

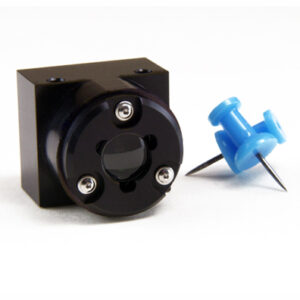

Van Nuys, CA – Motion Control Components – Moticont has released their OEM-00125U-01 Linear Optical Encoder Module and LS-00125U-01 Linear Scale. The compact linear encoder module measures just 51.5 mm (2.027 in.) long by 5.99 mm (0.236 in.) wide by 0.8 mm (0.073 in.) high. This high, 1.25 micron resolution, low power encoder module features TTL Quadrature Outputs and requires only a single +3.3 or +5 VDC supply.

Motion Control – Application – Minuteman Flange Blocks; 20 Million Cycles and Counting!

December 29th, 2025

December 29th, 2025  Editor

Editor Motion Control – Miniature Linear Focus Actuator Features <50 Nanometer Positioning Resolution!

December 22nd, 2025

December 22nd, 2025  Editor

Editor Motion Control – Miniature Linear Focus Actuator

Motion Control – LFA-1007 Linear Focus Actuator: 10mm clear aperture, 7mm range of motion, <50 nanometer positioning resolution, 50 grams moving mass, 70 x 70 x 50 (600g)

Forestville, CA — Motion Control Components – Linear Focus Actuator – The LFA-1007 is a high performance compact positioning actuator.

Motion Control – New! Three-axis Gimbal Mounts Feature High Resolution, High Load Capacity, Stability, and Four Motor Options!

December 15th, 2025

December 15th, 2025  Editor

Editor Motion Control – Three-Axis Stage!

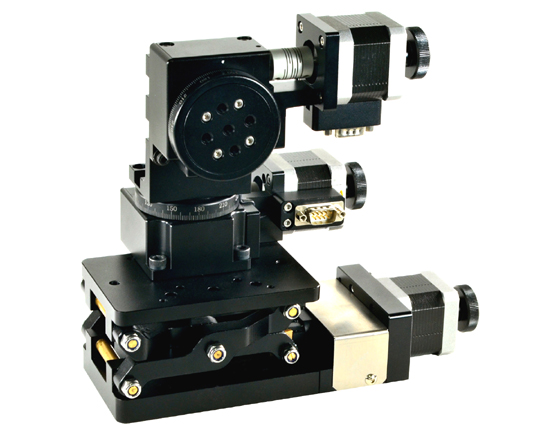

Van Nuys, CA – — Motion Control – Four high resolution, high Load, high stability three axis gimbal mounts have been released by OES (Optimal Engineering Systems, Inc.). These four new AU270-YPR Three Axis (Yaw, Angular Pitch, and Roll) Gimbal Mounts were developed to be used with larger and heavier: Cameras, telescopes, directional antennas, optics, lasers, tracking and scanning systems.

Motion Control – Meet the Voltage, Duty Cycle, and Force Requirements of Many Applications with a Series of 18 Push Type Open Frame Solenoids with a 1 Inch Stroke!

December 8th, 2025

December 8th, 2025  Editor

Editor Motion Control – Push Type Open Frame Solenoid

Motion Control Solenoids – Van Nuys, CA — Push Type Solenoids from Magnetic Sensor Systems (MSS) includes a series of 18 different low-cost open frame solenoids to select from based on the Voltage, Duty Cycle, Force of up to 96 oz (26.7 N) and stroke requirements of the user.

Motion Control – Electromate Adds Kollmorgen Essentials™ Servo Motion System to Its Product Lineup

December 1st, 2025

December 1st, 2025  Editor

Editor Motion Control – Servo Motion System

Vaughan, Ontario, Canada – Electromate Inc. is pleased to announce the availability of the Kollmorgen Essentials™ Servo Motion System in its offerings, reinforcing its commitment to providing accessible, high-performance motion control solutions to machine builders, OEMs, and automation integrators across Canada.

Motion Control – Miniature Linear Voice Coil Servo Motors Just 12.7 mm in Diameter Have 0.81N of Continuous Force and 2.55 N of Peak Force!

November 24th, 2025

November 24th, 2025  Editor

Editor Motion Control – Miniature Linear Servo Motor!

Motion Control – Van Nuys, CA – The LVCM-013-019-02M (Metric version) and the LVCM-013-019-02 (Imperial version) Linear Voice Coil Motors, just 12.7 mm (0.500 in.) in diameter, have been released by Moticont. Miniature brushless, efficient, high speed linear servo motors (known as Voice Coil and Moving Coil Motors) have a 12.7 mm (0.5 in) long stroke, a high-force-to-size ratio of 0.81 N (2.9 oz) and a peak force of 2.55 N (9.2 oz) at 10% duty cycle.

Motion Control – Miniature PVS 30.5 Parallelogram Voice Coil Stage from Equipment Solutions!

November 10th, 2025

November 10th, 2025  Editor

Editor Motion Control – Miniature Parallelogram Voice Coil Stage!

Forestville, CA, – — Motion Control – This Custom PVS-30.5 Parallelogram Voice Coil Stage Features: Flexture guidance system, 30 millimeter clear aperture, 4 millimeters of linear motion, 45 G’s acceleration (no load), 200 nanometers positioning repeatability, non-contact electro-optic position sensor, direct SCA-814 Servo Controlled Amplifier compatibility, 38mm x 46mm x 85mm, 280 grams.

Motorized Stages – Motion Control Multi-axis Lift, Pan, and Tilt Motorized Stage Features +/- 5 Micron Repeatability!

November 3rd, 2025

November 3rd, 2025  Editor

Editor Motorized Stages – Motion Control Multi-axis Lift, Pan, and Tilt Stage

Motorized Stages – Van Nuys, CA – Motion Control – The new LPT60-60-60 Series of Lift, Pan, and Tilt Motorized Motion Control Stages has been released by OES (Optimal Engineering Systems, Inc.). These compact stages feature a Lift-axis with 60 mm (2.362 in.) of vertical travel, a horizontally mounted Pan-axis (rotary) stage, and vertically mounted Tilt-axis (rotary) stage.

Motion Control Solenoids – Open Frame Series of 18 Pull Type Solenoids with a 1 Inch Stroke Can Meet the Voltage, Duty Cycle, and Force Requirements of Many Applications!

October 27th, 2025

October 27th, 2025  Editor

Editor Motion Control Solenoids – Open Frame

Motion Control Solenoids – Van Nuys, CA – The S-18-100 Series of Open Frame Pull Type Solenoids from Magnetic Sensor Systems (MSS) includes 18 different solenoids to select from based on the Voltage, Duty Cycle, Attractive Force (up to 100 oz) and Stroke requirements of the user. MSS Solenoid coils typically utilize 23 to 40 AWG (American Wire Gauge) windings with Class “F” insulation for better protection of the solenoid during longer duty cycles.

Motion Control – Compact 0.750 Inch Diameter Voice Coil Motor Features A 1.500 Inch Stroke and High Force-to-Size Ratio!

October 13th, 2025

October 13th, 2025  Editor

Editor Linear Motion Actuator – 1.0 Inch Diameter Voice Coil Motors!

![]()

![]()

Van Nuys, CA – Motion Control – Moticont has added a 0.750 in. (19.1 mm) diameter (smaller than a US Quarter) Linear Voice Coil Motor, to their expanding line of voice coil or moving coil motors.

The LVCM-019-048-02 Linear Voice Coil Motor is a true servo motor featuring zero cogging, high accuracy, and high repeatability when operated in a closed position loop. Voice Coil Motors (also referred to as actuators) are clean, quiet, efficient, brushless high speed linear servo motors. This small LVCM-019-048-02 diameter actuator has a 1.500 in (38.1 mm) stroke length and a high-force-to-size ratio of 7.4 oz (2.1 N) and a peak force of 23.5 oz. (6.5 N) at 10% duty cycle.