|

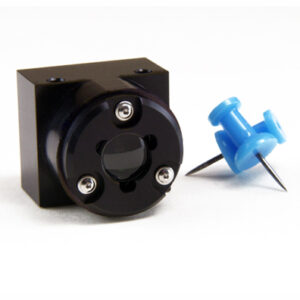

Sunnyvale, CA, — The RS-25 Resonant Scanner from Equipment Solutions is optimized for applications that typically require a means to scan an optical beam. This motion control resonant scanner is a very efficient means of oscillating or vibrating a mirror or similar load at a fixed frequency. Up to a 25 mm diameter mirror can be set at the factory to oscillate at a fixed frequency of 20 Hz to 550 Hz, and mirror sweep can be adjusted to a total of 90 degrees optical. The very compact RS-25 Resonant Scanner measurers just 25 x 58 x 21 mm and all electronics necessary to control and drive the scanner are fully integrated. Typical applications include: 3D laser digitizing & measurement, printing, raster scanners, laser projectors, laser marking, laser range finding, barcode scanning, confocal microscopy, FLIR, retinal image acquisition, semiconductor inspection, laser tuning, and biological and medical research.

The RS-25 Resonant Scanner can optionally be configured with a very high-resolution position sensor. This non-contact electro-optic sensor provides a means to directly monitor the angular position of the user’s load with micro-radian scale resolution and repeatability. The sensor naturally produces an analog signal proportional to position and is noise limited, however, options include a high-resolution 16-bit Analog-to-Digital converter to quickly sample and report the mirror position (up to 1500 samples-per-second) at any time.

Unparalleled performance and reliability have been achieved through a continuous and careful attention to every design detail. This relentless drive has generated patent pending concepts and ideas that distinguish the RS-25 Resonant Scanner. The RS-25 Resonant Scanner has a virtually unlimited life. Carefully designed flexures mimic a conventional spring-mass harmonic motion system, and a small voice coil motor coupled to the system compensates for small system loses that would otherwise dampen the oscillation.

Two connectors are accessible from the side of the unit. One, a mini USB connector, supports high speed USB communications and power sourcing. The second connector provides electrical control and signal interfaces (e.g. analog amplitude control and feedback (e.g.) mirror position).

Additional features include: Very low power drive electronics (low heat emission), vertical or horizontal mounting, high frequency stability (to 0.05%), broad frequency selection, no wearing parts, shock and vibration tolerant.

Equipment Solutions, Inc. (ESI) is a provider of engineering and manufacturing services. ESI specializes in the design and production of automation and instrumentation products including motion control components and sub systems. ESI’s products range from galvanometer amplifiers with an integrated arbitrary waveform generator, to high-resolution displacement sensors, voice coil and stepper motor stages, amplifiers and controllers.

For additional information contact Jeff Knirck at Equipment Solutions, 1098 West Evelyn Ave. #102, Sunnyvale, CA 94086; Tel: 408-245-7161, Fax: 408-245-7160, E-Mail:info@equipsolutions.com or visit the Website at http://www.equipsolutions.com

|

|

|

|

|

August 10th, 2012

August 10th, 2012  Editor

Editor  Posted in

Posted in