Motion Control – Rotational Scanner

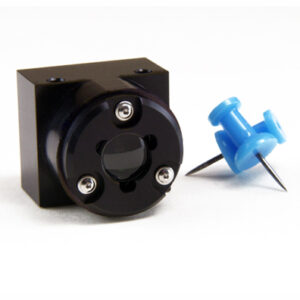

The Motion Control RVC-9025 Rotational Voice Coil Stage provides a means to quickly and repeatably steer an optical beam with a diameter of up to 25 millimeters over 90° with 25 microradians of resolution.

Forestville, CA, — The motion control RVC-9025 provides galvo like performance at a fraction of the size and cost. It is capable of positioning a mirror anywhere within its ±22.5° mechanical range in about a millisecond with micro-radian resolution.

The RVC-9025 also integrates a complete high-performance servo amplifier with both USB and low-level electrical interface. The choice is yours, you pick the interface that fits within your system architecture. All of this in a package that is about 60 x 30 x 20 millimeters, about the size of your thumb. The RVC-9025 uses the highest quality ball bearings available to support a lifetime of uncompromising performance. If your application requires rapid beam steering over a range of angles that exceeds the capabilities of today’s galvos the RVC-9025 should be at the top of your list. Straight forward integration, flexible interfaces, easy to use, reliability you can count on, the RVC-9025 Rotational Voice Coil Stage can help to make your next project a real success.

The Mirror: The mirror is an integral part of the motion control RVC-9025 and is usually specified at time of order. The mirror and its associated inertia will largely predict the overall step and settle time of the actuator. With that in mind the user should careful consider parameters surrounding the mirror including its shape and flatness. The mirror should be no wider than absolutely necessary and sufficiently long to accommodate the beam elongation as a consequence of the tilting process. Mirror flatness will largely dictate its thickness and overall inertia. In special cases, mirror thickness and its affects on inertia can be managed using costlier materials such as beryllium that have a higher specific stiffness. As the mirror thickness grows, its front surface will proportionally move further off the rotational axis which in some cases can be undesirable. Other parameters including coating and scratch/dig need to be included to fully describe the mirror. While a mirror is probably the most common payload other customer supplied or specified loads can be used such as gratings.

Position Sensor: The motion control RVC-9025 is able to position its mirror with a resolution of 25 micro-radians in a large part because of the high-resolution sensor it uses. The analog nature of its non-contact sensor also makes it noise limited by adjusting its bandwidth. Careful control and optimization of the sensor signal permits the servo to operate at a higher bandwidth and thereby having a higher stiffness and exceptionally low positioning wander or hysteresis.

Voice Coil Motor: The motion control RVC-9025 includes a high efficiency voice coil motor–somtimes referred to as a single phase DC motor. The motor coil is directly coupled to the mirror support beam and position sensor. That tight and rigid coupling of the load, actuator and sensor assures exceptional position repeatability and step-and-settle times. The high efficency of the motor coil yields a small and light-weight coil that adds little of the overall motion inertia.

Integrated Elecgtronics:The motion control RVC-9025 includes a highly miniaturized servo amplifier and controller. The mirror position can be controlled through either the USB and its 16-bit DAC or an analog input signal. At the same time mirror position can be monitored from and analog output or the USB and an optional 16-bit ADC. The auxillary input header also provides a means to enable the amplfier and monitor it for faults. Thereby supporting a configuration for a deeply embeded and autonomous device.

Equipment Solutions, Inc. (ESI) is a provider of engineering and manufacturing services. ESI specializes in the design and production of automation and instrumentation products including motion control components and sub systems. ESI’s products range from galvanometer amplifiers with an integrated arbitrary waveform generator, to high-resolution displacement sensors, voice coil and stepper motor stages, amplifiers and controllers.

For additional information contact Jeff Knirck at Equipment Solutions,Inc. Mailing Address – PO Box 159, Forestville, CA 95436; Shipping Address 6490 Front Street, Forestville, CA 95436; Tel: 408-245-7162, Fax: 408-245-7160, E-Mail: info@equipsolutions.com or visit the Website at http://www.equipsolutions.com

See this and other Motion Control Components from Equipment Solutions featured on:

http://MotionControl-XYZ-Theta.com

http://LinearMotionBlogger.com

http://MotionControlBlogger.com

http://MotionControlBuyersGuide.com

http://Catalogs-MotionControl.com

http://MotionControlMarketing.com

Go to Equipment Solutions Blog

May 21st, 2024

May 21st, 2024  Editor

Editor

Posted in

Posted in